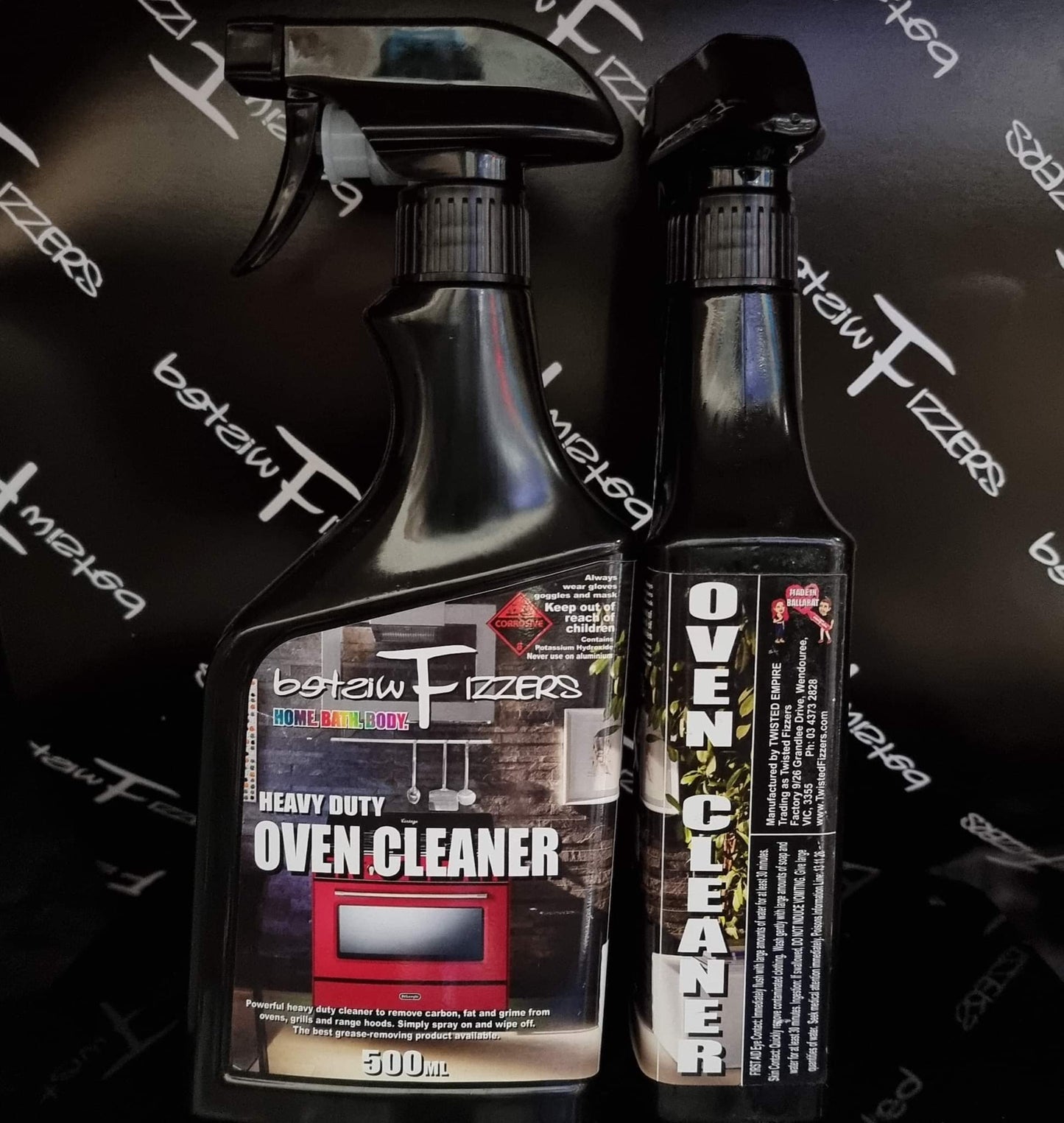

Twisted Fizzers

Oven cleaner - 500ml

Couldn't load pickup availability

Industrial strength.

Always wear gloves and mask when using this product.

Test on a small part first to ensure finish on the appliance is not affected. Do not use on aluminium or uncoated metal surfaces. Spray on, allow to sit for 5 minutes and wipe off

MSDS

1. IDENTIFICATION OF THE MATERIAL AND SUPPLIER Product Name Oven Grease Dissolver Other Names Caustic Potash Liquid 23%

Recommended use Dairy, food and beverage industriesOther Information This MSDS summarises to the best of our knowledge, the health and safety hazard information of the product and how to safely handle and use the product in the work place. Emergency Contact Details Poisons Information Centre 131126 2. HAZARD IDENTIFICATION Poisons Schedule (Aust) 6 Hazard Classification Hazardous according to the criteria of the Globally Harmonised System of Classification and Labelling of Chemicals (GHS) Hazard Categories Skin Corrosion/Irritation - Category 1B Serious Eye Damage/Irritation - Category 1 Acute Hazard To The Aquatic Environment - Category 1 Signal Word Danger Hazard Statements H314 Causes severe skin burns and eye damage. H400 Very toxic to aquatic life. Precautionary Statements Prevention P270 Do not eat, drink or smoke when using this product. P234 Keep only in original container. P264 Wash hands thoroughly after handling. P260 Do not breathe dust/fume/gas/mist/vapours/spray. P280 Wear protective gloves/protective clothing/eye protection/face protection. Response P301 + P312 IF SWALLOWED: Call a POISON CENTER or doctor/physician if you feel unwell. P330 Rinse mouth. P301 + P330 + P331 IF SWALLOWED: Rinse mouth. Do NOT induce vomiting. P303 + P361 + P353 IF ON SKIN (or hair): Remove/take off immediately all contaminated clothing. Rinse skin with water/shower. P363 Wash contaminated clothing before reuse. P304 + P340 IF INHALED: Remove victim to fresh air and keep at rest in a position comfortable for breathing. P310 Immediately call a POISON CENTER or doctor/physician. P305 + P351 + P338 IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing. P390 Absorb spillage to prevent material damage. Storage P405 Store locked up. P406 Store in corrosive resistant container with a resistant inner liner. Disposal P501 Dispose of contents/container in accordance with local / regional / national / international regulations. 3. COMPOSITION/INFORMATION ON INGREDIENTS Information on Name CAS Proportion Potassium Hydroxide 1310-58-3 23 % Sodium Hypochlorite ClHO.Na 7681-52-9 0.1 % Water 7732-18-5 Balance % 4. FIRST AID MEASURES Swallowed Have a patient drink large amount of water right away. Do NOT induce vomiting. If vomiting occurs, keep the head lower than the hips to maintain open airway and prevent aspiration. Seek medical treatment right away. Eye Immediately flush eyes with plenty of water for at least 15 minutes while holding eyelids open. Seek immediate medical attention. Skin Remove contaminated clothing. Wash affected area with plenty of flowing clean water for at least 15 minutes. Seek immediate medical attention. Wash clothing before reuse. If burned, treat as burn by acid. Inhaled Remove victim from exposure to fresh air. If not breathing, give artificial respiration. If breathing is difficult, give oxygen. Seek immediate medical advice. Advice to Doctor Treat symptomatically based on judgement of doctor and individual reactions of patient. Antidote : No antidote is available. In case of inhalation, oxygen supply must be considered. In case of ingestion, endoscopy of the oesophagus must be considered. Avoid washing out the stomach. The patient must be functionally cured according to symptoms. 5. FIRE FIGHTING MEASURES Flammability Conditions Not considered to be a fire hazard. Extinguishing Media In case of fire, appropriate extinguishing media include Powder extinguishant, carbon dioxide, water, general foam. Use minute water sprinkle, fog or regular foam in case of a big fire. After a fire extinguished, cool the containers exposed to flames by spraying with water for an extended period. Use large amount of water in mist type (Do not spray water directly on the material). Fire and Explosion Hazard Contact with combustible materials can cause explosions. Hazchem Code: 2X Hazardous Products of Combustion Thermal decomposition may produce toxic or / and corrosive fumes of potassium oxide. Personal Protective Equipment Fire fighters should wear a positive-pressure self-contained breathing apparatus (SCBA) and protective firefighting clothing (includes firefighting helmet, coat, trousers, boots and gloves) or chemical splash suit. Clear fire area of all non-emergency personnel. Stay upwind. Keep out of low areas. Eliminate ignition sources. Move fire exposed containers from fire area if it can be done without risk. Do NOT allow firefighting water to reach waterways, drains or sewers. Store firefighting water for treatment. Hazchem Code 2R No other Data Available 6. ACCIDENTAL RELEASE MEASURES General Response Procedure Emergency procedures, Evacuate the danger area or to consult an expert. Approach from upwind. Isolate the area. Wear self-contained breathing apparatus in confined spaces, in cases where the oxygen level is depleted, or in case of significant emissions. Prevent further leakage or spillage if safe to do so. Keep away from incompatible products. Clean Up Procedures Soak up spilled product using absorbent non-combustible material such as sand or soil. Avoid using sawdust or cellulose. When saturated collect material, transfer to suitable, labelled, dry chemical-waste containers and dispose of promptly as hazardous waste. Isolate the container from contaminated area, mark and remove it to safe area. Neutralize the floor surface with acid materials (weak hydrochloric acid, weak sulfuric acid, etc.) after diluting it with large amount of water. Soil exposure: Dig a hollow in the ground where it spilt. Build a bank using earth, sand bags, or blowing agents such as polyurethane or concrete in order to stop it flowing and to keep it in the bank. Adsorb the liquid using slack lime, soda, ashes, cement powder. Use a weak acid to neutralize. Spill in the atmosphere: Reduce vapour occurrence by spraying water as a spray. Collect the spilt substance to dispose of it as potential hazardous waste. Underwater spill : Neutralize the material with a weak acid. 7. HANDLING AND STORAGE Handling Warning - To avoid a violent reaction ALWAYS add material to water and NEVER water to material. Ensure an eye bath and safety shower are available and ready for use. Avoid contact with heat, open flames, sparks and other sources of ignition. Observe good personal hygiene practices and recommended procedures. Wash thoroughly after handling. In case making the diluted solution of potassium hydroxide, be sure to put potassium hydroxide into water (Absolutely do not put water into potassium hydroxide). Avoid bodily contact and persons handling potassium hydroxide must always wear protective goggles, protective suit and protective gloves as listed in section 8. Upon being contacted with this material, it destroys the cell of the skin, so absolutely do not work with bare hands. Remove contact lenses before starting any work. Do not smoke or have food while working. Do not inhale product vapours. Avoid prolonged or repeated exposure. Remove contaminated clothing and wash before reuse. Storage Store in a cool, dry, well-ventilated area. Keep containers tightly closed when not in use. Inspect regularly for deficiencies such as damage or leaks. Protect against physical damage. Store away from incompatible materials as listed in section 10. Storage container should be airtight. Keep it in isolation from an acid, organics (woollen fabrics, leather, etc.), metal, NITROMETHAN, and CHLORINATED SOLVENT. Attention must be paid so that a potassium hydroxide solution may not be frozen in winter. This product has a UN classification of 1814 and a Dangerous Goods Class 8 (Corrosive) according to The Australian Code for the Transport of Dangerous Goods By Road and Rail. Container polyethylene, Do not store in steel, copper, tin, aluminium or its alloy containers. 8. EXPOSURE CONTROLS/PERSONAL PROTECTION General The following exposure standard has been established by The Australian Safety and Compensation Council (ASCC); Potassium Hydroxide [Caustic Potash] CAS 1310-58-3: TWA = 2mg/m3 Peak Limitation. NOTE: The exposure value at the TWA is the average airborne concentration of a particular substance when calculated over a normal 8 hour working day for a 5 day working week. Peak limitation is a ceiling concentration which should not be exceeded over a measurement period which should be as short as possible but not exceeding 15 minutes. These exposure standards are guides to be used in the control of occupational health hazards. All atmospheric contamination should be kept to as low a level as is workable. These exposure standards should not be used as fine dividing lines between safe and dangerous concentrations of chemicals. They are not a measure of relative toxicity. Exposure Limits No Data Available Biological Limits No information available on biological limit values for this product. Engineering Measures A system of local and/or general exhaust is recommended to keep employee exposures as low as possible. Local exhaust ventilation is generally preferred because it can control the emissions of the contaminant at its source, preventing dispersion of it into the general work area. Adequate ventilation should be provided so that exposure limits are not exceeded. Personal Protection Equipment RESPIRATOR: Self-contained breathing apparatus with full face-piece operated in the pressure demand. For emergencies or instances where exposure levels are not known, use a full face piece positive pressure, air supplied respirator. Warning! Air -purifying respirators do not protect workers in oxygen deficient atmospheres (AS1715/1716). EYES: Chemical splash goggles and/or face shield must be worn when possibility exist for eye contact due to splashing or spraying liquid or vapour (AS1336/1337). HANDS: Wear PVC, rubber or neoprene gloves. Glove thickness has to be of minimum 1.2 mm. Do not use leather gloves (AS2161). CLOTHING: Wear impervious protective clothing including boots, lab coat, apron or coveralls and safety footwear (AS3765/2210). Work Hygienic Practices Always wash hands before smoking, eating, drinking or using the toilet. Wash contaminated clothing and other protective equipment before storage or re-use. 9. PHYSICAL AND CHEMICAL PROPERTIES Physical State Liquid Appearance Liquid Odour Odourless Colour Transparent / Opaque Reactions That Release Gases or Vapours If this reacts to water, it attacks metal such as aluminium and tin, lead or zinc, resulting in generating a hydrogen gas. No other data available 10. STABILITY AND REACTIVITY Chemical Stability Product is stable under normal conditions of use, storage and temperature. Corrosive Liquid. Conditions to Avoid Avoid heat, a flame, spark, other ignition unit. Hazardous gas can be accumulated in a closed space (explosion). Materials to Avoid Incompatible with oxidizers such as perchlorates, peroxides, permanganates, chlorates, nitrates, chlorine, bromine, fluorine, etc. Avoid contact with Nitric acid, Acid, Acrolein, Alcohol, Aluminium, Ammonium salt, Benzoyl chloride + Sodium azide, Para-bis(1,2-Dibromoethyl)benzene, Bromoform, Bromoform + Cyclic polyethylene oxide, Calcium carbide + Chlorine, Chlorine dioxide, Chlorine + hydrogen peroxide, Chloroform + methanol, 1,2-Dichloroethylene, Cyclopentadiene, Geranium, Glass, Halogenated hydrocarbon, nitride, Lead, Anhydrous mallein, Metal, N-Methyl-NNitrosourea + Methylene chloride, Trichloro nitric acid, Alkane nitrate, Nitro benzene + Methanol, Nitro ethane, OrthoNitro phenol, Nitro propane, N-Nitrosomethylurea + N-Butylether, Phosphorous, Peroxi potassium disulphate, Potassium peroxodisulphate + water, sugar, Tetrachloroethane, 2,2,3,3-Propane tetraflouride, Tetrahydrofuran, Thorium dioxide, tin, Trichloroethylene, 2,4,6-Toluene trinitrate + Methanol, and zinc. Hazardous Decomposition Products On thermal decomposition, it generates poisonous fume of potassium oxide. Hazardous Polymerisation Refer to Condition and substance to avoid. If this reacts to water, it attacks metal such as aluminium and tin, lead or zinc, resulting in generating a hydrogen gas. It actively reacts to melted O-nitrophenol, and if potassium hydroxide and tetrachloroethane are heated, a chloroacetylene gas which naturally takes fire is generated. If it reacts to 1,2dichloroethylene, chloroacetylene which naturally takes fire is generated. If it is heated with phosphorous, a phosphine gas which naturally takes fire is generated. It is incompatible with an acid, water, metal, halogen hydrocarbon, and maleic acid anhydride. Polymerization reaction : Not polymerized. If it melts in or contact with water, alcohol or acid solution, exothermic reaction arise. 11. TOXICOLOGICAL INFORMATION General Information Oral toxicity L LD50=333mg/kg b.w (Rat : Sprague-Dawley) Serious eye irritation : Reported as causing irreversible damage in human and in a rabbit Draize test. Severe exposure may cause pneumonia, circulatory failure and peritonitis. KOH is not a mutagen because negative results were obtained in bacterial reverse mutation assay and in a mouse bone micronucleus test. Eye Irritant Causes eye damage. Eye damage, category 1. Eye contact causes serious burns and discomfort. Ingestion Causes severe pain, nausea, vomiting, diarrhoea, and shock. May cause haemorrhaging of the digestive tract. May cause corrosion and permanent tissue destruction of the oesophagus and digestive tract. May be harmful if swallowed. Inhalation Irritant. Inhalation of sprayed solution and vapours can cause respiratory system irritation caught, difficulty of breathing, stomatitis, nausea and pulmonary edema. Skin Irritant Causes severe burns on short term exposure. Long term exposure may have the same effect reported on short term exposure. If this contacts the skin, it slowly penetrates the skin, and the cell of the skin is gelatinized. Carcinogen Category No Data Available 12. ECOLOGICAL INFORMATION Ecotoxicity Toxicity to fish : LC50=80mg/L, 96hr, Gambusia Affinis (non GLP) Toxicity to daphnia magna : EC50=660mg/L, 48hr, Daphnia magna (non GLP) Toxicity to algae : EC50=1337mg/L, 120hr, nitscheria linearis (non GLP Persistence/Degradability log Kow -3.88 Environmental Fate Do NOT let product reach waterways, drains and sewers. Bioaccumulation Potential bioaccumulation : BCF 3. 162 Readily Biodegradable. 13. DISPOSAL CONSIDERATIONS Dispose of at approved disposal sites. Follow local regulations. 14. TRANSPORT INFORMATION Land Transport (Australia) ADG Proper Shipping Name POTASSIUM HYDROXIDE SOLUTION Class 8 Corrosive Substances Subsidiary Risk(s) No Data Available EPG 37 Toxic And/Or Corrosive Substances Non-Combustible UN Number 1814 Hazchem 2R Pack Group II Special Provision No Data Available 15. REGULATORY INFORMATION Poisons Schedule (Aust) 6 16. OTHER INFORMATION In case of poisoning call the Poison Information Centre, phone 131 126. This MSDS summarises to the best of our knowledge the health and safety hazard information of the product and how to safely handle and use the product in the workplace. . . . End of MSDS. . .